We have already covered:

Step 1: The Equipment: Getting Started – Early October – A list of everything you need to make wine and where to find it.

Step 2: Grape Selection – A guide to choosing the right grape.

Step 3: Sanitizing – The importance of maintaining a clean work area and proper sanitizing procedures.

WINEMAKING (October / November)

Day 1: Sorting and Treading – The first day of the wine-making process, including stomping on the grapes.

Day 3 – 10: Punching and Fermenting – Caring for the grapes, adding nutrients and monitoring the fermentation process.

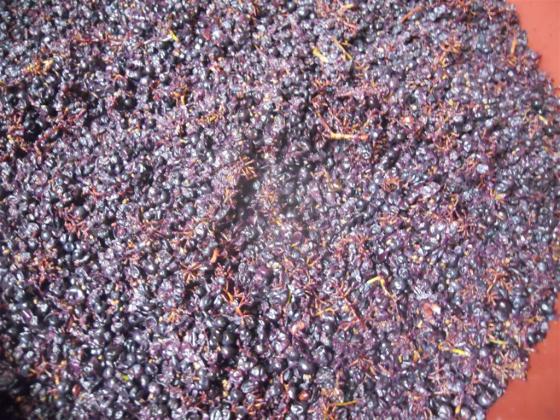

So, you’ve been punching and stirring your grapes 2x day and you’ve been taking a hydrometer reading daily. It can take anywhere from 3 to 26 days for your grapes to be ready.

When the hydrometer reads 0 or – 1… It’s time to Press Those Grapes!

Sanitize the Press:

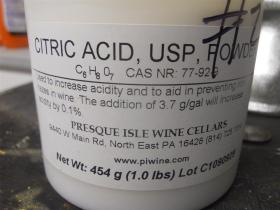

Thoroughly sanitize your press with Soda Ash and Citric Acid.

Use 1/4 cup of Soda Ash dissolved in 1 gallon of water. Brush the press clean and then discard the solution and rinse with plain water. Follow the same instructions using the Citric Acid.

Sterile Rinse:

Give the demijohns a sterile rinse by dissolving 4 tablespoons of META in 1 gallon of water. Run this solution through all of the demijohns shaking the bottles as you go. Rinse with plain water.

Sit your press on a table with the empty, sanitized demijohns (carboys) on the floor near the press. Place a large funnel into one of the demijohns and sit it directly under the spout of the press so that the juice can fall directly into it.

Using a large pitcher or pail, scoop out some of the grapes and juice and start filling the press. The juice that pours out from the press is called “free run” juice because you have not pressed it yet. This is the best quality so you want to spread it across all of your demijohns evenly. Some of the world’s most respected wineries will use only this “free run” juice for their best or reserve wines and then use the pressed juice for their less expensive wines.

After your vat has been emptied into the press and all the “free run” juice has been spread evenly among all the demijohns you can begin to press the grapes to realease the remaining juice, topping off all of the demijohns. It’s good to have help in doing this so that one person can remove a full demijohn as another person replaces it with a half full demijohn without spilling too much .

The wine should be very alive at this stage, warm and bubbly…that means it’s fermenting!

Place a bung into each demijohn and tape it down with clear packing tape. If you don’t tape it down, the natural gases will cause the bung to fly out. Take your sterilized fermentation traps and fill them halfway with water. Poke a hole through the tape and insert a fermentation trap into each bung. The wine will bubble as the gas slowly escapes through the traps.

Place the demijohns in a warm place (65 – 75 degrees) for 7 days to complete the fermentation process.

NB: Thoroughly clean the press and all other tools and equipment.

You can also prepare the wine area for next week’s crucial step of siphoning (racking) the wine to clean demijohns. I’ll also discuss winter storage and cold stabilization.

See you then!

~

© Giovanni Cucullo 2011